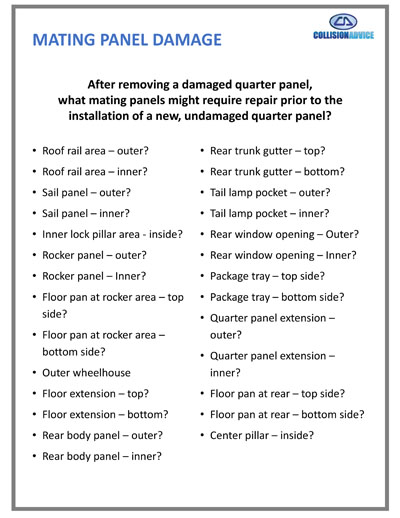

An often overlooked estimating item is the repair of adjacent, or “mating," panels after the removal of a damaged panel. For example, once a rear body panel is removed, the trunk floor will have to be repaired in order to fit the new panel. It’s also not uncommon for taillight pockets, rain gutters, troughs and sometimes even the frame rails to require some repair.

Yet our “Who Pays for What?” survey earlier this year found more than 1 in 10 shops acknowledge never having sought to be paid for this work---despite the fact about two-thirds of shops report being paid for this “always” or “most of the time” by the eight largest national insurers when it is necessary and performed.

I always suggest a four-question process when negotiating for this or any non-included operation.

1. Is it required to fully and properly repair the vehicle?

It’s obvious when looking at the condition of these adjacent panels that it is. It’s virtually impossible to remove a welded panel without causing damage to the adjacent panels or attaching components.

2. Is adjacent panel damage included in any other labor operation?

All three of the major estimating system providers agree that it is not. The “labor exclusions” portion of the Audatex/Solera Database Reference Manual, for example, clearly states “repair labor does not include additional labor to repair the replaced panel and/or adjacent panels which may become distorted, burned or damaged by welding, drilling, grinding and straightening.”

Similarly, the Motor Information Systems’ Guide to Estimating---the basis for the CCC Intelligent Solutions estimating system---includes a special notation about welding zones and adjacent panels. It says labor operation times do not include time for repair of adjacent panels resulting from normal cutting, welding and grinding procedures.

And Mitchell International’s Procedure Pages lists under “additions to labor times” the repair of “parts adjacent to parts being replaced.”

If you don’t have copies of any of these documents from the Big Three estimating systems, you can download them at no charge from the “Estimator’s Toolbox” section of the Database Enhancement Gateway (DEG) website.

3. Do the estimating system providers provide a pre-determined time or calculation method for this procedure?

Again, the answer is no. “The amount of damage can vary considerably depending upon process and technique used by the servicing technician,” the note in the Motor Guide to Estimating states, for example. “Motor recommends these factors be considered before finalizing any repair cost estimates.”

4. If it’s necessary and non-included, what is it worth?

Though repair of adjacent panel damage is clearly necessary, it is a judgment item. Your experience will help you know how much time the process is likely to take, but you also can help justify your judgment times through some videotaped time studies within your shop.

Although I’ve focused here on the repair of the adjacent panels, there may be other non-included procedures and items as well. Refinishing may require blending into these adjacent panels---top and undersides. Time may be needed to match the look of factory seam sealers. Sound deadening pads are often included on these panels, and if damaged during removal of a panel, they will need to be repaired or replaced.

In short, damage to adjacent panels can add significant time to a repair, and these steps should be documented on your estimates.

Read more from Mike Anderson