In the late 1970s, acrylic enamel paint was becoming more commonplace in body shops. However, Rick Selover, national account manager for Garmat USA, said it was tacky, sticky and didn't dry quickly like lacquer. As a result, it became critical for shops to have a spray booth.

“That's when the battle started for a clean job,” recalled Selover. “It became a lot more a lot more important that you did some kind of preventative maintenance to keep yourself from getting a ton of dirt and contaminations in your paint jobs.”

Fast forward to the present, and Selover said many shops are still facing the same challenges with dirt and contaminations.

During the Southeast Collision Conference in May, he shared insight on how to deal with common paint defects and avoid the true costs of contamination.

“It's a wake-up call,” said Selover, who hosts the Mind Wrench podcast and the Collision Cocktail Hour. “I'm sharing some real-world facts and conditions that some people probably need to make some changes so they don't incur these costs or losses of production.”

Selover said 100% of jobs have some dirt.

“It's really, really rare you'll get a completely flawless finish,” he noted. “Even some OEM finishes allow about three to five specks per square foot.”

However, most of the dirt is preventable.

“Dirt in the base coat can't just simply be buried and maintain acceptable mil thickness,” Selover explained. “That’s going to be unacceptable and cause problems later on.”

Instead, he said it must be sanded, outside of the booth, and the base coat reapplied. It’s the same with dirt nubs in clear coat, which can be removed with wet/dry sanding and polishing. Excessive sanding and polishing can compromise clear mil thickness and cause durability failures.

Selover noted fisheyes are random and can cause major redos; however, the majority are preventable.

“Burying fisheyes doesn't work,” he said. “It just leads to bigger problems.”

Fisheyes in top coat must be sanded out, also outside the booth, and the clear or base/clear reapplied.

Selover noted fisheyes are random and can cause major redos; however, the majority are preventable.

Selover noted fisheyes are random and can cause major redos; however, the majority are preventable.

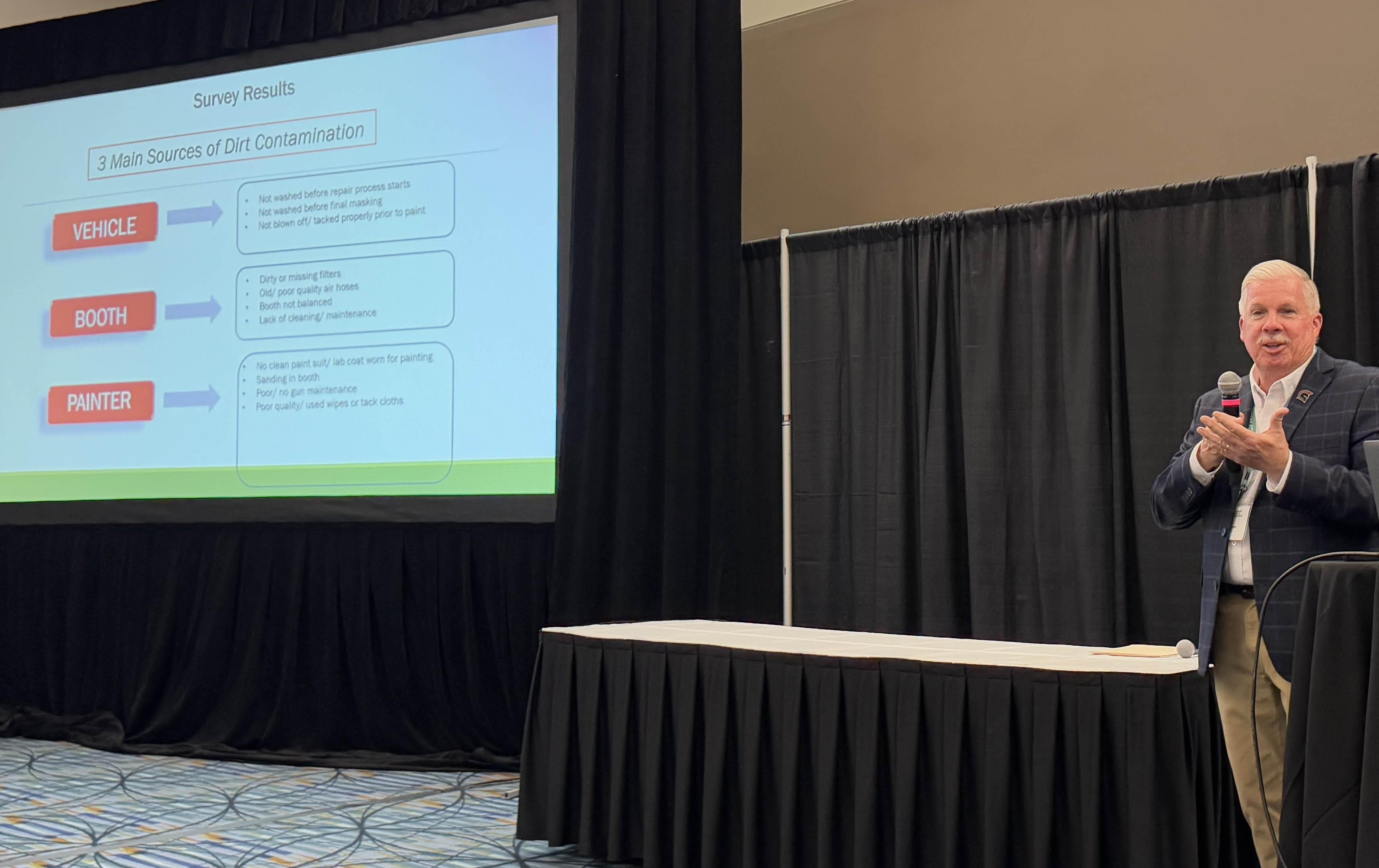

Sources of fisheye contamination can sometimes be challenging to locate and eliminate. He said the three primary sources of dirt contamination are the vehicle (10%), the booth (40%) and the painter (50%).

He used the example of vehicles not being washed before the repair process starts, before final masking or not being blown off/tacked properly prior to being painted.

Issues with the booth may include dirty or missing filters, old or poor-quality air hoses, the booth not being balanced and a lack of cleaning/maintenance.

In terms of painters, dirt contamination can occur due to not wearing proper personal protective equipment (PPE) when painting, sanding in the booth, poor or no gun maintenance and poor-quality/used wipes or tack cloths. Other sources of contamination include poor final preparation, improper masking/taping, no anti-stat process and dirty parts stands in the booth.

Selover also discussed the main sources of fisheyes. For vehicles, which account for 46% of fisheyes, he found they typically come from silicone-based products on vehicles/tires, surfaces not properly cleaned/degreased and improper chemical storage inside the vehicle.

With booths (34%), he said fisheyes can appear due to contaminated compressor/air lines/filters, a poorly maintained air compressor, outside contaminants that are drawn into the booth and contaminated ceiling filters.

Fisheyes from painters (20%) can be from personal care products or not wearing PPE, what Selover referred to as “pizza-hands” when painters don’t wash their hands after lunch, no gloves worn during the final prep, poorly maintained spray equipment and silicone-based products in the paint area.

Top 10 Culprits for Dirt/Contaminants Based on Selover’s Research

1. Dirty filters

2. Painter not wearing proper PPE when painting

3. Booth not balanced properly

4. Lack of booth maintenance or cleaning

5. Old or poor-quality air hoses

6. Failure to completely wash/blow out vehicle before final masking

7. Sanding in booths

8. Poor-quality wipes/not changing tacking cloths or using dirty ones

9. Poor gun maintenance

10. Not using an anti-stat gun

Other offenders include improper masking/taping, a dirty area around the booth, dirty air blowers, painting with the door open, poor surface/prep cleaners, food in the beard or mustache, dandruff and sweat drops.

Top 10 Contaminants for Fisheyes

1. Air lines/compressor

2. Silicone-based products on car

3. Using non-body shop-friendly products

4. Painter not wearing proper PPE

5. Air filter systems not maintained

6. Improper prep

7. Poor equipment maintenance

8. Outside air contaminants

9. Handprints/no gloves

10. Improper storage of materials

Additional culprits include not purging cleaning solvent after cleaning the gun, humidity in the booth water in the pit or air system, no air line filter system, contaminated gun washers, silicone-based cleaners used on the interior body, deodorant, and hand/body creams or hair products.

Selover talked about what he called the “influencer factor,” referring to those who have influence over these tasks being completed. He used the example of a painter who should identify whether the filters are dirty and need to be replaced, if fresh hoses are needed or if the car was completely degreased and decontaminated before going into the booth.

Selover encouraged shop owners and managers who want to clean up their shops, achieve better finishes, and reduce rework and redos to be aware of these influencers.

The High Cost of Rework

Selover then discussed the outcome of dirt and contaminants — the high cost of rework. This includes the additional cost of paint and materials, energy, lost production revenue and employee retention.

The three primary sources of dirt contamination are the vehicle, the booth and the painter.

The three primary sources of dirt contamination are the vehicle, the booth and the painter.

He shared an example of the paint and materials cost to a shop using an average repair order (RO) of $4,350, based on CCC’s Q1 2024 Crash Course Report. If the average paint cost to the shop is 3.9% of sales and the materials cost is 1.7% of sales, the cost of paint and materials per RO is $244. With a two-day rental car, the cost rises to $362. If there are two redos per month, that equates to $723.20 or $8,678.40 per year.

“That’s not counting lost production,” Selover emphasized.

He also addressed the cost of wasted utilities. If the average booth time per RO is 1.4 hours, the energy cost is $17.30, based on an electric cost of $0.194 cents/kWh and a $1.40/therm natural gas cost. With two redos per month, that equates to $34.60 per month and $415.20 per year.

The lost cost of production based on the average RO sales of $4,350 and two booth cycles per day is $8,700 for two redos per month and $104,400 per year. Based on two redos per month, Selover estimates the annual total cost of additional paint and materials, wasted utilities and lost production revenue is $113,496.

Lastly, he outlined the cost of lost technician income based on a flat rate of $22 per hour and a $4,350 RO. “A paint tech loses an average of $297 on every average RO job he or she must redo along with 1.4 hours of booth time,” he explained. “Even if a technician has one redo per month, that’s still a $3,500 yearly loss in potential income.”

There is also the cost of retaining employees.

Selover said a good production painter earns about $1,726 per week.

“Most painters will stay put when their main ‘money-maker’ — the spray booth — is kept in good working condition, clean, well-lit and has regularly scheduled maintenance done by someone else besides themselves,” observed Selover.

If the booth is down due to a lack of proper maintenance and a painter typically completes four booth cycles a day, Selover said a shop will have about $17,400 a day in lost production, based on an average of $4,350 per cycle.

“If a painter quits due to no maintenance or multiple stoppages in work due to worn or non-serviced equipment, the loss in production would be the same, as well as the cost of hiring and training a new painter, which is more difficult to do when equipment is ill-maintained or semi-functional,” he explained.

One solution to these challenges, according to Selover, is to integrate the paint department’s best practices and create standard operating procedures (SOPs).

“The large MSOs have been doing this for years and there's a reason for it,” he noted. “It guarantees repeatability and results.”

By implementing and monitoring SOPs, Selover said it protects a shop’s investment throughout the equipment’s lifecycle. He suggests devising SOPs that address booth, vehicle and painter hygiene.

“If a surgeon walked in to operate on somebody with his blue jeans and a T-shirt on, it’s probably not going to be a good scenario,” said Selover. “It seems like a stretch, but I think a painter should have that same mentality.”

The goal is to ensure nothing goes wrong.

Selover also suggested shop owners and managers implement a preventative maintenance program.

“Stop leaving the preventive maintenance up to the painter,” he said. “They don't want to do it. They'd rather have somebody that does that for a living come in and do that.”

He recommended protecting the shop’s most significant assets — people and equipment — and scheduling a dependable, repeatable preventive maintenance monthly, quarterly or annual program with the booth distributor.

“It may cost a little bit of money for preventive maintenance, but it's well worth it,” he shared. “Doing preventive maintenance on your vehicle or your booths makes a massive difference on your investment and the results.”

Over the years, Selover has found service and maintenance programs drive cost savings, prolong the life of the equipment, ensure reliability and enhance employee safety and productivity. They also help shops stay compliant with regulations, improve quality finishes, reduce energy consumption and enhance their reputation and employee retention.

“The goal is to identify and address issues before they escalate into costly major repairs by mitigating downtime, enhancing operational efficiency and extending equipment lifespan,” he explained.

To ensure the booth never goes down, he reminded shop owners, managers and technicians to replace the exhaust filters and ceiling filters at regular intervals.

“Overloaded intake filters can cause balance issues and create negative pressure,” he mentioned.

An annual deep cleaning of the booth is also recommended. By taking care of the booth, Selover said there will ultimately be less rework and reuse.

“A clean and bright booth to paint in facilitates safety, color matching and painter satisfaction,” he noted. “A clean booth equals cleaner jobs and less wasted resources, as well as improved employee retention and customer satisfaction.”

For questions, email ricks@garmat.com or visit www.garmatspraybooths.com.

Stacey Phillips Ronak