Since GM and supplier Llink Technologies launched a headlamp remanufacturing process in 2021, the program has evolved to reclaim 95% of headlamp components that would have wound up in landfills, far exceeding its initial goal of 25%, the automaker announced in a news release.

Headlamps are one of the most commonly damaged components in a collision, second only to bumpers. While many components that make up a headlamp can be salvageable, due to insurance company preferences on claims, headlamp assemblies are often replaced with less expensive aftermarket parts during collision repair, sending many usable parts to landfills.

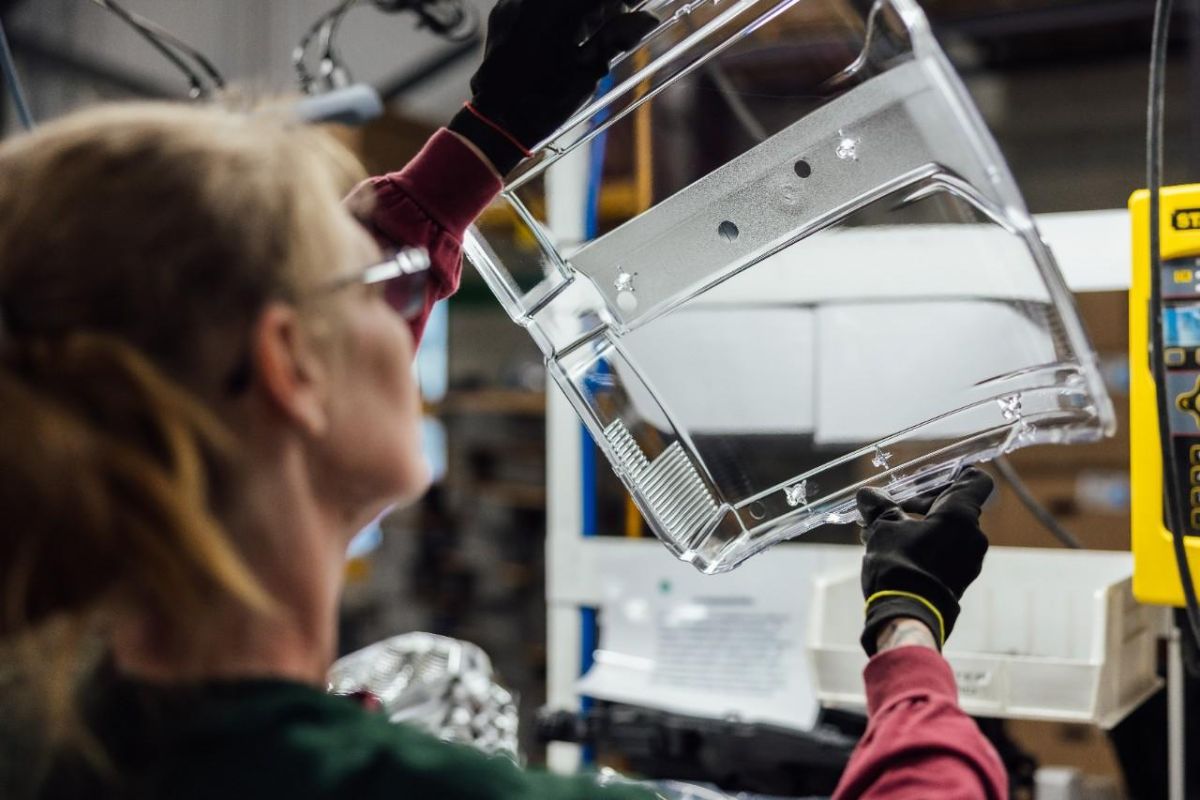

In 2017, a cross-functional team from GM identified this as an opportunity and began developing a headlamp remanufacturing process with Llink Technologies. The process replaces the headlamp housing and lens, reuses internal components such as integrated circuit chips, materials and fans, and tests each assembly to ensure it meets OEM standards and specifications.

In 2021, the first program launched with the 2016–2019 Chevrolet Silverado, which was enthusiastically received by customers and insurance companies, to the point that every remanufactured headlamp ended up in customer vehicles. Remanufactured headlamps are currently available for select 2016-19 Silverado models, select 2018-20 Equinox models and will be available on additional vehicles in the future.

The GM remanufactured headlamps are produced to meet OEM specification requirements and quality with a two-year GM Parts warranty, while being cost competitive with the aftermarket headlamps, which insurance companies appreciate.

“With the initial program launch alone, we’ve salvaged and repurposed headlamp components that would fill more than 100 semi-truck trailers,” said Jeff Goulet, CEO of Llink Technologies. “I’m proud of the work our team does to help GM meet the needs of its customers and support sustainability efforts.”

Llink Technologies can reuse between 70% and 90% of each headlamp housing that is returned, and any non-usable parts such as the lens, housing or damaged materials are recycled. Additionally, 100% of the packaging---including the boxes and foam---is reused for shipping the remanufactured headlamps back to customers.

According to Llink Technologies, up to 80% less energy is consumed by remanufacturing compared to aftermarket manufacturing.

“We set out to do something new in the industry that was good for business, and that helped drive us toward a more sustainable future,” said Tod Stump, manager, GM Global Remanufacturing. “Since 2021, more than 13,000 headlamps have been remanufactured and there are plans to expand the program. We’re excited to be the first to create a headlamp remanufacturing program that can be a model for other programs in our industry. It’s a great example of how we are bringing our cultural goals---being bold, looking ahead and innovating now---to life.”