I read a sobering article in The Washington Post recently that I think offers some insights into where vehicle technology is likely headed.

The article featured an interview with Jeffrey Michael, who spent three decades at the National Highway Traffic Safety Administration (NHTSA), and is now at the Johns Hopkins Center for Injury Research and Policy.

He’s a car guy. The article said when he’s home, he likes to tinker on the 1987 Porsche 911 he bought as a fixer-upper. While he was with NHTSA, he worked on issues related to seat belts, child restraints, drunken driving and emergency medical services.

But the article also said this:

“Michael saw the ability of federal programs to influence safety and cites a gradual reduction in road deaths over 50 years. But in an interview with The Washington Post---days after new NHTSA figures showed fatalities hitting a 16-year high---Michael pointed to the nation’s failure and potential fixes.”

Make sure you read that again. Roadway fatalities have reached a 16-year high.

You have to believe NHTSA and other regulators are going to place an even greater emphasis on vehicle and roadway safety. You have to believe the automakers are going to be pushing forward on getting more and better ADAS and telematics features into vehicles. That’s going to impact the vehicles we have coming into shops.

Michael also noted in the interview, “To improve things, we’re going to need to individually make concessions about convenience, about driving a little slower, about taking a little more care, about personal responsibility, of using our seat belts, of driving at or below the speed limit, of driving responsibly, certainly driving without impairment, without fatigue, without distraction.”

The “using our seat belts” portion of that quote caught my eye. Our industry has a vital obligation to make sure those seat belts have been inspected after a vehicle has been in an accident. Every automaker has very specific requirements about this.

Even when General Motors revamped its post-collision vehicle inspection requirements, for example, its stance on seat belts did not change. GM wants “every seat belt of every [GM] vehicle inspected every time” a vehicle is in for repairs, “regardless of the [crash] severity level or what’s being done” to the vehicle, said John Eck, collision manager for GM.

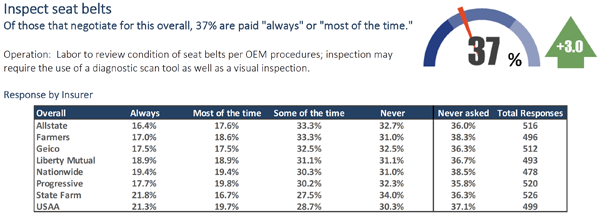

We’ve been asking about seat belt inspections in our “Who Pays for What?” surveys dating back to 2016. On the surface, the news is good. Back in 2016, close to two-thirds of shops said they’d never billed for the labor involved in inspecting seat belts, and among those who had, fewer than one in four said they were paid for that work by the eight largest national insurers “always” or “most of the time.”

In the seven years since, the percentage of shops not billing for the work has fallen, and the percentage being paid regularly has grown.

But looking at the numbers still keeps me awake at night. As of this year’s survey, there were still 28% of shops---more than one in four---that acknowledged never having billed for seat belt inspections. I have to believe many of those shops aren’t doing this critical work, perhaps because they’re not researching and following the OEM procedures.

And in the seven years we’ve asked, never have more than two in five shops billing for this work said the insurers regularly pay for it. How can the insurance industry deny payment for this needed step? And though shops are morally---if not otherwise---obligated to do it even if they’re not paid for it, are insurer payment practices contributing to it not being done on every single vehicle?

Ladies and gentlemen, it often doesn’t require any more than looking at the vehicle owner’s manual to document the seat belt inspection requirement. In the resources section of the “Who Pays” body labor report, we point to an excellent list of links to vehicle owner's manuals, put together by the Database Enhancement Gateway (DEG).

You can take the current “Who Pays for What” survey during July here.

In some cases, in addition to a visual inspection, the OEM procedure may require the use of a diagnostic scan tool to check the pre-tensioners. On some Honda and Acura vehicles, for example, a deployed pre-tensioner does not trigger a diagnostic trouble code, so other “live data” from the scan must be checked. In these cases, it’s important to know I’ve read of instances where shops have found their aftermarket scan tool didn’t catch blown pre-tensioners an OEM scan did.

I encourage you to check the NHTSA website for some sobering statistics about highway deaths, and some tools you can use to help educate your customers.

But we also all need to make sure we’re not contributing to the problem, by repairing every vehicle fully and correctly, including the seat belt and other OEM safety inspections.

Mike Anderson