For body shop owners and managers who are still “winging it” when scheduling repair jobs, there is a better way to manage the process and proactively run a collision repair shop, according to Dave Luehr and Ron Kuehn.

Luehr, owner of Elite Body Shop Solutions, and Kuehn, owner of Collision Business Solutions, teamed up during an Elite Body Shop Academy webinar to teach body shops how to schedule optimum WIP (work in process), create a balanced workflow, optimize a shop’s work mix and create a simple scheduling form.

“In today’s collision repair world, old thinking and poor scheduling systems are a recipe for disaster,” said Luehr. “Modern shops can no longer afford to bring in a majority of their week’s work in on Mondays and expect to survive.”

When Luehr meets with shop owners and managers to help manage their businesses, his first operational priority is to look at their scheduling process and optimum WIP.

“You can’t implement anything successfully in an environment where you have too many cars sitting around,” he said. “The best blueprinting efforts typically fail because [owners] don’t understand scheduling and optimum WIP.”

Why Most Scheduling Systems Don’t Work

Many shops across the country schedule jobs based on labor hours, the number of cars or dollars. Although there is nothing wrong with scheduling this way, according to Kuehn, there is a tremendous opportunity to analyze the information available to a repair facility and fine-tune the scheduling process.

Luehr added that the labor hours used to schedule jobs aren’t always accurate due to incomplete estimates. This can create a tremendous amount of instability, not only with scheduling but also with the entire production system.

In a typical body shop, Luehr said, the culture has always been to “grab the keys” for as many jobs as possible. However, that approach often isn’t effective, especially in some markets across the country.

“It’s killing people,” said Luehr. “It seriously creates health problems from the amount of stress and chaos that goes on every day in a typical body shop.”

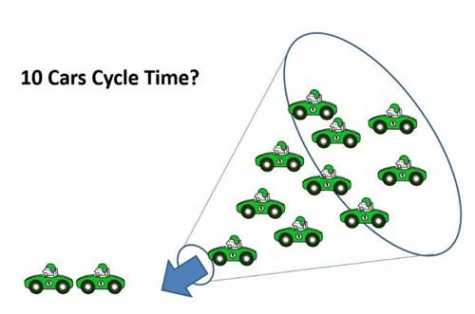

Kuehn said some shop owners and managers find comfort in knowing they have a lot of work on the shop floor and premises. However, he said, more often than not, the bigger the parking lot they have compared to the number of technicians, the worse the shop’s cycle time is going to be. Kuehn often calls shop owners like these “wipaholics”---those who don’t mind having too much work in process.

Luehr said another main reason most scheduling systems aren’t effective is that shops “push” work through the shop, rather than allowing production to “pull” work from a pool of production-ready jobs. Instead, he recommends determining the needs and capacity of the shop’s production system and bringing in just the right amount of production-ready work to feed it.

Excess WIP has been found to drive up operating costs, leading to poor cycle time, cash flow problems, quality defects and wasted resources.

“If your WIP is too high, cycle time can suffer and chaos ensues,” said Luehr. “If it is too low, revenue can suffer.”

Kuehn said three key ingredients need to be addressed: a shop’s WIP; monitoring intake and system of repair planning/blueprinting to identify what is needed regarding labor and parts up front; and most importantly, leadership.

“Leadership has to set the tempo,” said Kuehn. “You have to come up with a number, then you have to monitor it and see what works and what doesn’t and continue to make modifications to make it better.”

Learning to Schedule to Optimum WIP Using Little’s Law

Luehr also discussed Little’s Law, a mathematical equation for cycle time, introduced to him by Rich Altieri from AutoBody Management Solutions.

Using the model of Little’s Law, Luehr said, shops can design their desired cycle time days and then figure out how many cars to ideally have on the property.

To calculate optimum WIP, divide the number of cars on the property (WIP) by the daily production units (the average number of vehicles delivered daily). That will tell a shop its average cycle time.

For example, if a shop with 10 cars in its production system consistently produces an average of two per day, it translates to a five-day cycle time. In contrast, a shop carrying 20 cars on the property would have a cycle time that would double to 10 days on average.

Creating a Balanced Workflow

When scheduling for production, Kuehn said, most management systems include four dates: arrival; repair start (when a technician is ready to work on the vehicle and it can hopefully go through the system without stopping); repair complete (when the file is finished, ready to close and the vehicle is completed and inspected); and delivery.

“The time between the start or ‘repair time’ and complete time, which you can think of as your manufacturing plant, is where you make your money,” said Kuehn. “The more efficient you can make your manufacturing plant, the more cash velocity [a component of cash flow] you are going to have.”

In a perfect world, Luehr said, a shop should bring in the same number of vehicles per day that are delivered to help maintain optimum WIP. For example, in a shop that repairs 20 cars per week, four would be brought in each of the five days it’s open and four would be delivered each of those five days.

“That would create the optimum workflow that would allow your business to be firing on all cylinders at its most profitable state,” he said.

“The bottom line is to monitor intake because you can’t afford to have those cars sitting around,” said Kuehn. “You have an investment in all of those cars and a lot of cash tied up. It’s not just about getting those cars through the shop; it’s also the administration you have that can backlog the shop and your office.”

Optimizing Work Mix

Wise shops, according to Luehr and Kuehn, implement “triage” methods and bring in a mix of work each day. Different triage methods can be used based on the number of estimating hours, number of damaged panels, dollars spent and drivable vs. non-drivable vehicles. While many of these methods work well for shops, Luehr said it can often complicate the process. Instead, he recommends using a simple category size triage system using dollars or labor hours.

For example:

Category 1: $0-$1,499

Category 2: $1,500-$3,999

Category 3: $4,000+

“By overloading your system and not having the proper mix because you have too many small jobs at any one point in time, it will slow down the overall work,” said Kuehn.

In other words, to keep all departments running at optimal profitability, he said, a mix of small, medium and large jobs need to be scheduled throughout the week.

How to Create a Simple Schedule Form

Luehr said a good first step is to create a scheduling form to maintain optimum WIP and revenue goals. Every repairable vehicle should be accounted for on the form, regardless of the actual arrival date.

If no openings are available, then the shop probably shouldn’t bring in another car, he said. If a loyal customer happens to come in, he said shops will likely agree to repair the car but will have to let the customer know the timeframe.

“At least you have a scheduling system that allows you to communicate a little smarter with your customer,” said Luehr.

“If you get ahead of schedule, you can always blueprint the vehicle and pull it into production, but don’t force-feed it,” said Kuehn.

Luehr said the typical work mix for DRP shops can be determined by pulling historical data from the shop management system, and then space can be created on the scheduling sheet for those vehicles.

“You may not know exactly how many are coming in or when, but you can still block out space for them,” he said. “The worst thing that could happen is maybe one doesn’t show up and then you can bring in somebody else ahead of schedule.”

Luehr cautions shops not to be too aggressive when reducing optimum WIP (car count) because it takes time to improve. He recommends decreasing the work in process incrementally while continuing to refine the shop’s systems to avoid losing revenue.

Kuehn agrees.

“You can’t change your culture overnight,” he said. “Instead, you need to start with a scheduling process gradually and fine-tune the system.”

“The ultimate goal is to simultaneously achieve your revenue goals and cycle time goals and adjust to keep your optimum WIP on target,” said Luehr.

For an example of Elite Body Shop Solutions’ scheduling form and to watch the free webinar, visit https://daveluehr.mykajabi.com/schedulingwebinar.

Stacey Phillips Ronak