As advanced driver assistance systems (ADAS) continue to reshape modern vehicle technology, repair shops are under mounting pressure to adapt. During a June 9 webinar hosted by Kaizen Glass Solutions and Revv, collision professionals gained an in-depth look at the growing complexity of ADAS-related repairs, and how the Revv platform is helping body shops simplify calibration, documentation and compliance.

With more than 4,000 collision centers across North America already using Revv’s integrated software, and Kaizen Glass providing hands-on training in ADAS calibration, this partnership is proving vital for shops navigating today’s rapidly changing vehicle safety landscape.

The Cost of Skipped Calibrations

During the webinar, Revv’s Joel Adcock and Spencer Fox walked attendees through real-world examples of how the platform identifies missed calibrations and integrates with estimating systems from CCC, Mitchell and Audatex.

The message was clear: failing to complete required calibrations is both a safety hazard and a financial liability. According to Revv, 80% of ADAS calibrations are currently skipped, and up to 37% of repair costs — roughly $1,540 per job — may be tied to calibration-related operations that often go unbilled.

A live demo showed how Revv flags required procedures for common models like the 2022 Honda Accord and 2025 Chevy Silverado, identifying systems such as Forward Collision Warning, Lane Keep Assist and Blind Spot Monitoring that require static or dynamic calibration post-repair. The system provides OEM documentation, pricing tools and invoicing functionality directly within the platform.

Why Glass Operations Are Moving In-House

One of the key drivers behind ADAS calibration complexity is the glass itself. Modern windshields are no longer just structural components; they play a vital role in a vehicle’s advanced safety systems.

Along with the advantage of safety features, consumers are attracted to ADAS features such as blind spot warning and automatic emergency braking.

Along with the advantage of safety features, consumers are attracted to ADAS features such as blind spot warning and automatic emergency braking.

“Windshields are critical components of a vehicle’s safety system,” said Shauna Davis, president of Kaizen Glass Solutions. “They house cameras, sensors and heads-up displays. Improper handling during replacement can compromise calibration, safety and, ultimately, the integrity of the entire vehicle.”

Davis has worked with body shops across the country to bring glass and calibration operations in-house — a trend gaining momentum as shops seek to control quality and reduce delays.

In a separate Autobody News interview, Lupe Gonzalez of C and S Body Shop shared that outsourcing glass work used to delay repairs by up to six days. “That downtime was hurting our business,” he said. After bringing glass work in-house using Kaizen’s training, his team completed five windshield jobs in just a few days.

Carlos Manzo of U First Auto Body echoed the benefits. “Having everything in-house assures us we know everything in real time,” he said. “Our turnaround time dropped from a month to two weeks.”

Training for Today’s Vehicles, Not Yesterday’s Windshields

Kaizen offers a comprehensive training program that combines auto glass replacement and ADAS calibration, enabling shops to upskill their technicians and recapture lost revenue quickly. According to Davis, the average shop can see a return on investment after just eight windshield replacements.

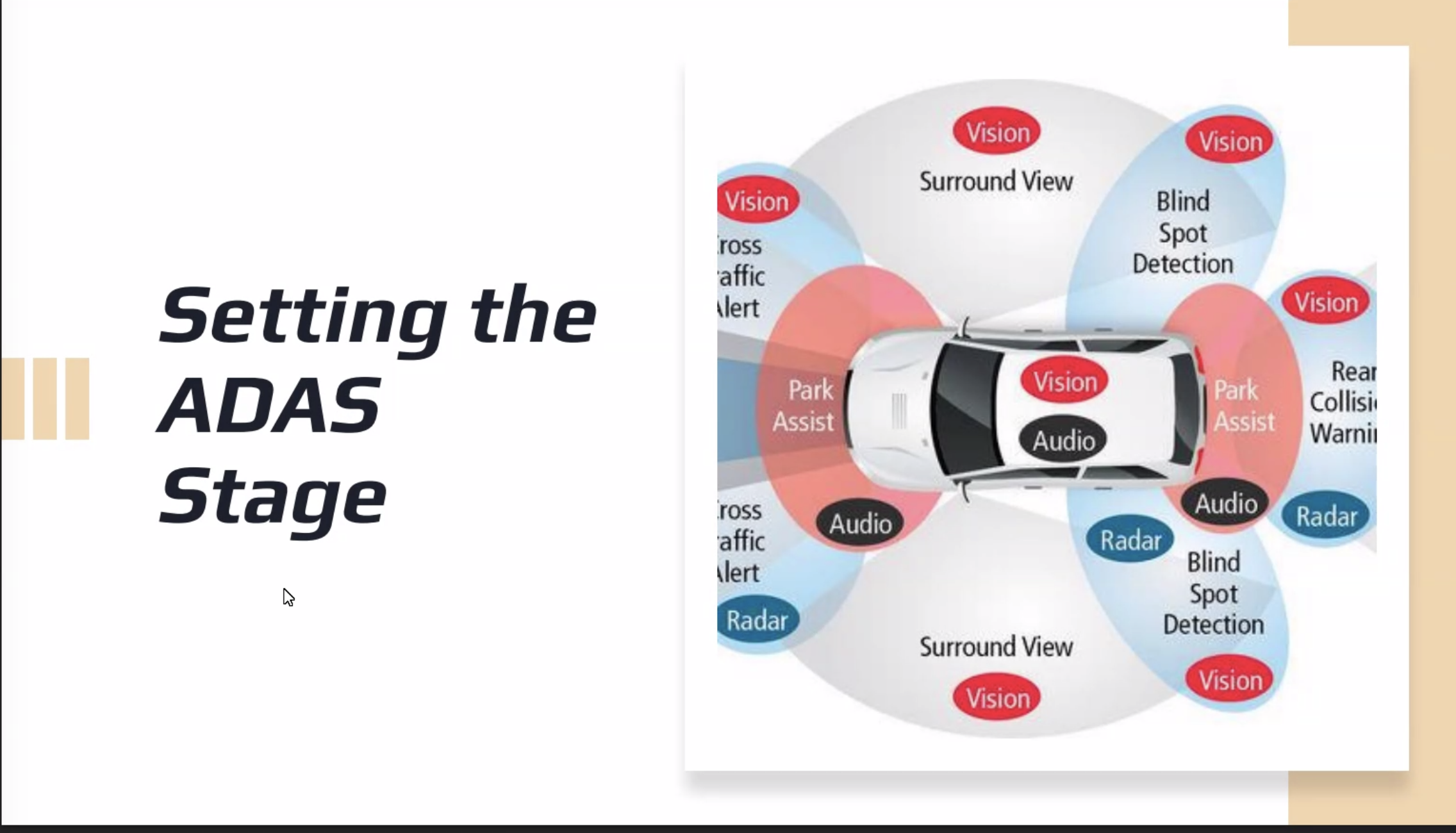

Modern vehicles rely on a complex web of vision, radar and audio sensors. Understanding where and how ADAS systems operate is key to performing safe, OEM-compliant repairs.

Modern vehicles rely on a complex web of vision, radar and audio sensors. Understanding where and how ADAS systems operate is key to performing safe, OEM-compliant repairs.

The training covers tools such as wire cutting systems and Panther Pro Fit setting devices, which enable a single technician to safely handle complex replacements. “These tools improve time management and reduce technician fatigue,” Davis explained during the webinar. “They help shops attract and retain talent.”

Kaizen’s curriculum also emphasizes recalibration following glass replacement, recognizing the rapid evolution of windshield technology. Davis noted today’s advanced windshields often require specialized handling, and improper replacement can compromise critical features such as heads-up displays and adaptive cruise control. With embedded radar and LiDAR systems becoming more common, especially in electric vehicles, the need for proper procedures and post-installation calibration is more important than ever.

Trends Shaping the Auto Glass Industry

The webinar highlighted how Kaizen and Revv are enabling shops to stay ahead of industry shifts. In a recent Autobody News article, Davis identified several key trends, including:

• Smart Glass: Newer vehicles feature electrochromic dimming, HUDs and AR navigation displays. These technologies demand precision replacements to avoid post-repair failures.

• Stricter Regulations: Insurers are demanding proof that technicians are properly trained and certified. A new FMVSS related to calibration procedures is under discussion, which could further raise compliance standards.

• Rising Consumer Expectations: Today’s customers value convenience and safety. Offering full-service repair — including ADAS calibration and glass replacement — enhances customer loyalty and differentiates shops in competitive markets.

Tech-Driven Future for Collision Shops

With more than 92% of U.S. vehicles now featuring some form of ADAS, and the global ADAS market expected to top $210 billion by 2034, calibration is no longer optional. It’s essential.

That’s where Revv comes in. The software streamlines what used to be a manual, error-prone process by delivering clear repair triggers, step-by-step documentation, and even downloadable invoices tied to each calibration.

For shops already handling their glass work in-house, platforms like Revv help them document calibration needs, justify charges to insurers and close the loop on safety-critical procedures.

To learn more about training options, visit www.revvhq.com or contact Spencer@revvadas.com. For auto glass and calibration training, visit www.kaizenglasssolutions.com.

Leona Scott